Everad makes a distinction between heat-activated hot-melt adhesives and pressure-sensitive adhesives.

Joints with heat-activated adhesives must be bonded within a specific time frame, known as the “open time”. PSAs (pressure-sensitive adhesives) on the other hand remain permanently adhesive. After coating, the adhesive film must be covered with a protective layer.

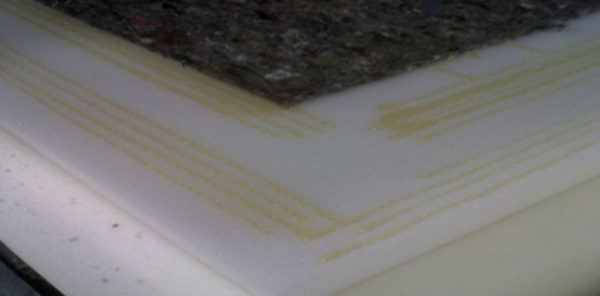

Polyurethane hot-melt adhesives reticulating with humidity, they offer high heat resistance and tensile strength once the reaction is complete.

To manufacture hot-melt adhesives, raw materials such as polymers, resins, plasticisers and additives are blended at high temperature in mixers. The resins and plasticisers are worked into the polymer.