Everad proposes a wide range of one- and two-component polyurethane- and silane-based reactive adhesives as well as others based on new raw materials developed by the chemical industry.

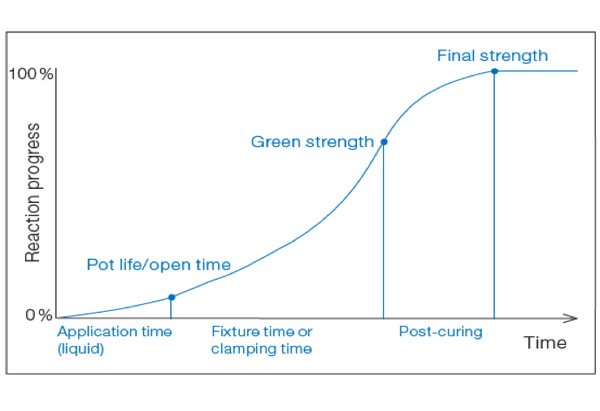

1-C adhesives harden in the presence of humidity in the material or in the air whereas, in 2-C adhesives, the two components react with each other. An increase in temperature can accelerate setting.

REACTIVE ADHESIVES HAVE A WIDE VARIETY OF APPLICATIONS:

- Sandwich panels and panels for partitions, ceilings and insulation

- Panels for refrigerating elements and metallic containers

- Panels for door and gate construction, tunnel doors

- Special doors (protection against radiation, fire, noise)

- Front panels

- Panels for the transport industry (HGV bodies and floors, wagon doors and ceilings)

- Wooden structures, staircase construction

- Casting resins for electrical components, industrial filters

- Sundry mounting jobs

- Bonding of soft foam (sponge manufacturing or temperature- or humidity-resistant complexes)