The manufacture of water-based adhesives is generally split into two stages: polymerisation and formulation. Everad does not polymerise directly but relies on its close cooperation with the LAS Group companies that specialise in this field and other long-standing partners.

Everad can therefore influence the adhesive’s profile according to the choice of monomers and stabilisers.

We then formulate our Everad adhesives in mixers to manufacture products that are ready to use.

THE EVERAD RANGE INCLUDES A WIDE VARIETY OF WATER-BASED ADHESIVES:

- One- and two-component contact adhesives for bonding foam

- Dispersions for impregnated foam

- Pressure-sensitive dispersions (PSA)

- Water-based binders for material manufacture

- High solid content dispersions (up to 83% solid content)

- Wood glues

-

Euroclass A1-fire retardant glues and sealants

-

Heat-activatable adhesives

-

Solvent-free adhesives “by design”

-

FR (flame retardant) adhesives

-

Viscosities adjustable on demand to suit the process

-

Application laboratory for tests and prototypes.

Everad is one of the first companies to have invested in water-based contact adhesive technology which, at the time, was seen as a ground-breaking innovation. In twenty years, we have become a leading specialist in water-based contact adhesives – the alternative to solvent-based glues.

In keeping with its multi-technology strategy, Everad works continuously to propose a complementary range of one- and two-component adhesives to meet the precise needs and increasingly stringent demands of customers, thanks especially to the application equipment and processes suited to their use.

EVERAD CONTACT ADHESIVES OFFER THE FOLLOWING BENEFITS:

- Solvent- and VOC-free

- Ease of use

- Possibility of single-spread application

- Simplification through spray-on and roll-on versions

- High initial tack in one-component systems, and very high initial tack in two-component systems

- Bonding under very high pressure

- Ultra-quick setting and rapid drying

- High final cohesion

- Flexible joints

- Pink colouring of the adhesive that becomes invisible after spraying

- Repositioning possible

- Versatile bonds

- High yield

- Variable open time that adapts to your production constraints

- Bonding of difficult materials (moulded foam, plastics, etc.)

- Version withstanding plasticiser migration

- Chlorine-free version complying with the requirements of standard ISO 16000-9 and Nordic Ecolabeling recommendations

- Exclusive system to increase glue ageing protection and improve the durability of your end products

- Reduced spray mist

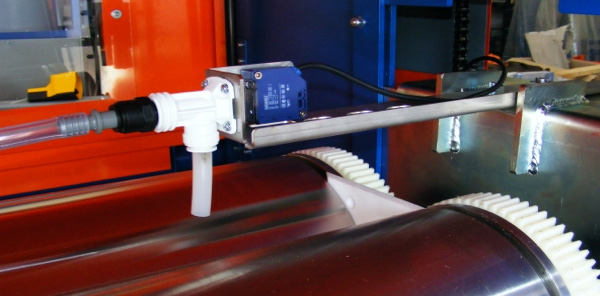

- Regular application of the adhesive by roller

- Reduced investment in application equipment

- Various types of applicator: sprays, rollers, spatulas, bead guns, slot dies

- Easy cleaning adapted to the process