Adhesive films are produced by placing the ingredients (especially polymers and additives in pellet form) in an extruder where they are melted, homogenised and extracted by the extruder screw. The resulting melt is then spread out in the extrusion die. A film of the required thickness is produced by extruding the melt with a slot die for flat film, or an annular die for blown film, and then cooling.

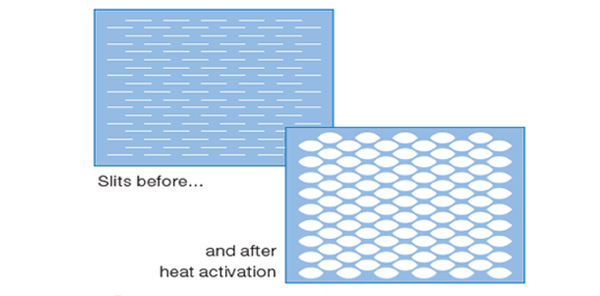

The films can also be slit. Slits approximately 4 to 8 mm in length are cut in the film to make it softer and air permeable, and also shrink the film by heat transfer when the slits open up.